Window profiles, door profiles and gate profiles

Comprehensive expertise and offers for successful production

Thanks to our long years of experience, we have a lot of know-how relating to roll forming machines for window profiles, door profiles and gate profiles. This ensures you can produce your windows, doors and gates significantly better and more inexpensively than the competition.

Tailor-made system technologies

Our cooperation with you starts with product design: Our engineers assess the feasibility of individual profile shapes for windows, doors and gates. In this way they give you valuable information about how your profiles can be optimally produced. In addition, it is possible for you to subcontract near-series prototypes of the new product for sampling or market tests. This reduces your financial outlay and minimises imponderables arising during product development.

An example of our novel roll forming functionality is the thermal cutting of profiles, which is combined with innovative options for reducing energy use and CO2 emissions. To do so, we have developed our own solution approaches, which can be adapted to the specific requirements of individual products. Another example in the area of window profiles, door profiles and gate profiles are innovative surface coatings which give the profiles a new look.

Irrespective of which requirements are your priority: We produce the tailor-made system technology for you. The result is convincing: Products with new functionalities and a process reliability, which continuously and reliably ensures both high quality and the economic success of your whole project.

Examples of roll forming machines for window profiles, door profiles and gate profiles

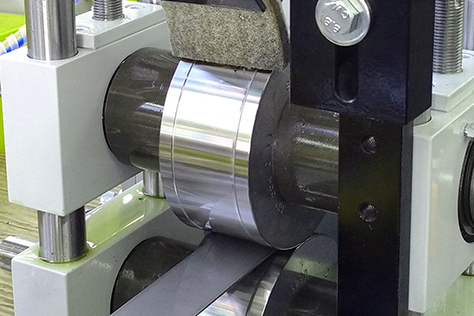

Our roll forming machines for the sector comprising window profiles, door profiles and gate profiles are in many respects ground-breaking.

Door frame system

- Frame widths from 60-310 millimetres

- Dependent on the product range, various system types are available

- Production velocity from 10-30 metres per minute dependent on part length and punching pattern

- Customised punching

- Order-specific production

- Unexcelled service life of the roll forming tools

- User-friendly touchpanel with job management software.

Contact our construction industry experts

Each sector has its own special requirements, which is why your company too will have its own special questions about roll forming machines and processes: Our roll forming experts in the construction sector have all the answers you need!