Multilayer composite pipes

From pioneer to trendsetter for innovative and custom technologies

When we produced the first roll forming system for multilayer composite pipes in 1984, no one could envisage what unbelievable success this pipe would have: within just a few years, it became Europe’s favourite multilayer composite pipe for heating and mains water pipes.

Easy and quick laying

The success story of our pioneering work was based on the combination of the best properties of metal and plastics: The multilayer composite pipes have the temperature and pressure resistance of metal pipes combined with the corrosion-resistance of plastic pipes. They can be easily bent and retain their shape after bending. Therefore they can be quickly and easily laid. Using our roll forming systems, you can produce multilayer composite pipes with production rates of up to 60 metres per minute and with an extremely low scrap rate.

If you need to change the pipe dimensions, then our roll forming systems score due to their short changeover times: In a benchmarking test they demonstrated the shortest changeover times. Depending on your requirement, we will simply supply you with the roll forming system part for the production of the aluminium pipe or, alternatively, a turnkey complete system.

As a pioneer of composite technology, we continue to work constantly on further applications for composite pipe technology: In doing so, we have demonstrated that composite pipe systems can also process copper and stainless steel. For a thickness of just 80 µm, this opens up interesting new applications with persuasive cost benefits, especially for stainless steel composite pipes.<br/>

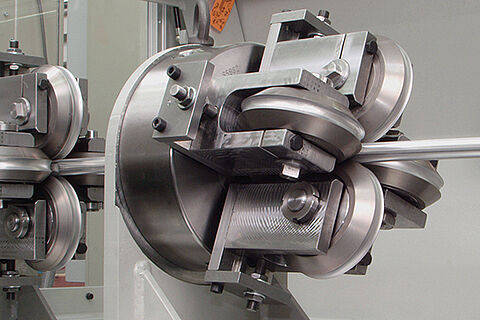

Examples of roll forming machines for multilayer composite pipes

You benefit from our decades of experience when using our roll forming machines in the field of multilayer composite pipes.

Contact our construction industry experts

Each sector has its own special requirements, which is why your company too will have its own special questions about roll forming machines and processes: Our roll forming experts in the construction sector have all the answers you need!