Uprights

High productivity for applications in small or large areas

Our modular machine concepts for uprights extend from roll forming machines for household and lightweight racks through to roll forming systems for heavy duty shelves and silo structures. References from rack manufacturers across the world demonstrate that we offer the correct concept to every manufacturer.

Maximum process reliability for minimum material costs

The large fraction of material costs for the uprights within your rack production requires an economical handling of the materials. Just as important for you here is a maximum process reliability and around the clock availability. You can achieve all this objectives with our roll forming systems.

The high productivity of our roll forming machines offers you many advantages. In this case, it means maximum production rates and in other cases, quick setups without extended down times for different profile dimensions. <br/>

With our roll forming systems for uprights, you achieve maximum production speeds, because the entire process chain from the strip feeding system to the pre-punching system to the roll forming machine and cut-off machine are optimally designed for your individual requirements. With our highly flexible roll forming solutions, you will achieve changeover times of just a few minutes: in this way you optimally implement a comprehensive range of profiles and order based production.

Examples of roll forming machines for uprights

With our roll forming machines for uprights, we are providing you with roll forming solutions that are perfectly matched to your requirements.

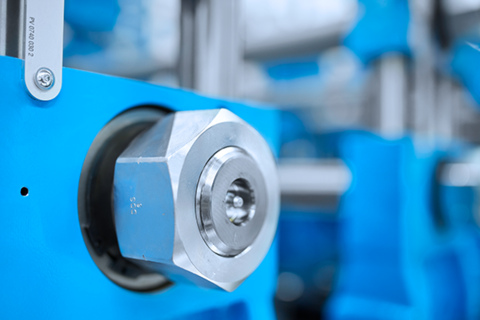

Profile punching and cutting unit

Suitable for post-punching and cutting to length.

- Flying cut-off machines for high production rates or profiles with an integrated welding process

- Stationary cut-off machine for an average production rate

- Rotary embossing unit for economic, continuous marking of the profiles

- Cut-off tools for low-burr separation cuts

Options

- Integrated pre-punching systems in the form or a rotary die cutter or punching unit with intelligent feed and tool technology for automatic setting up of pre-programmed hole patterns

- Strip end welding machines

- Modern tool fast coupling systems for high system availability

- Inline welding for closed profiles (HF or laser)

- Inline after galvanizing of welded joints for continuous corrosion protection and a uniform visual appearance

Contact our Storage & Logistics sector experts

Each sector has its own special requirements, which is why your company too will have its own special questions about roll forming machines and processes: Our roll forming experts in the storage & logistics sector have all the answers you need!