Ideal combination of

high safety and low weight

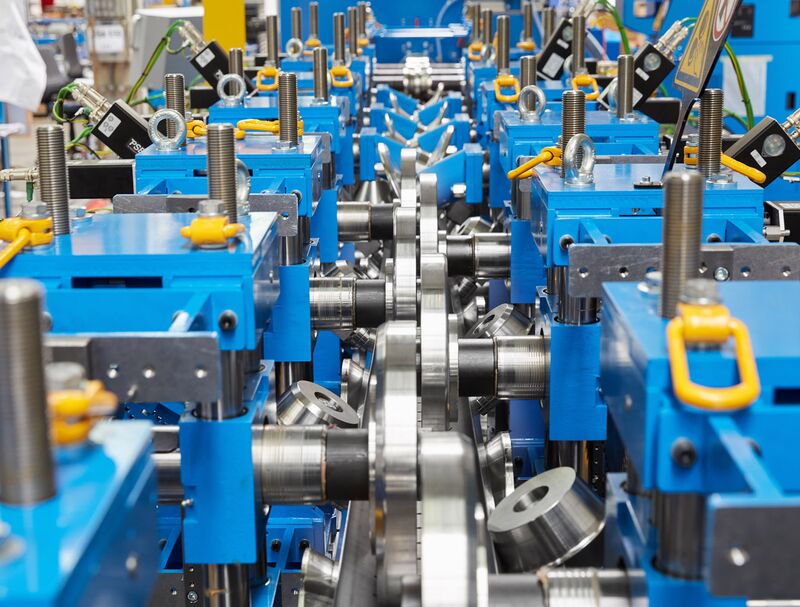

Profiles for commercial vehicles must be absolutely safe and very light: You can fulfil both requirements with our roll forming machines. Our special roll forming processes provide you with the flexibility of timing presses, but are much faster and more productive.

Large cost and time advantages

All cross-section dimensions of standard profiles can be changed within a few minutes without additional tools and across a continuous range. This means you benefit from considerable cost and time benefits when producing a wide range of parts.

Often roll forming is just one of many process steps in the production of complete, installation-ready parts. Therefore, it is very easy to integrate welding, punching and embossing operations in our roll forming systems. This simplifies your production process and also saves costs. Moreover, operators of our roll forming machines value the process reliability: our roll forming systems consistently deliver precision parts, that can be automatically installed or further processed without any problem.

Professional roll forming machines

clearly presented

Form your own impressions of the precision and reliability of our roll forming machines: The video shows you clearly some of the advantages of our roll forming systems and processes.

Examples of roll forming machines

for commercial vehicle parts

Our roll forming machines in the commercial vehicle parts sector provide you with the required individuality.

Strip feeding systems

Within an overall concept, you will also receive the appropriate strip-feeding system from us: It is used for the continuous supply of the roll forming system with the raw material, the flat strip and make an important contribution to the productivity of the overall system and the quality of the parts.

Highly automated strip systems perform a complete coil change in 3 minutes, including welding of the strip ends. Precision-alignment systems and a low-stress strip feed into the downstream punching or roll forming machines provide the necessary conditions for the production of precision components with the narrowest of tolerances.

Pre- and post-punching systems

The integration of pre-and post-punching systems is of particular importance for the production of production-ready body components: In doing so, you will minimise the number of downstream process steps and associated costs while simultaneously improving the product quality. Dependent on your requirement, we will put into practice concepts for ensuring maximum production performance or for more extreme requirements, targeting flexibility and the range of parts. Flexibility implies production performance of up to 80 parts per minute. Where, the range of parts is concerned, changeover times of a few minutes are possible. The number of punch operations that can be integrated, is almost unlimited. A major advantage for you is the Start-Stop® operation introduced by us: Here the roll forming machine operates like a precision roller feed, feeding the completed parts with high positional accuracy to the press and punching tools.

Roll formed part

With our roll forming machines you will achieve high production speed and very low material consumption. In contrast to press manufacturing there is practically no cutting scrap. A third, essential advantage for you are tooling costs which are also lower in comparison. In the past, roll forming was viewed as relatively inflexible because of the longer changeover times. Thanks to new changeover technologies, our roll forming systems are amongst the most flexible manufacturing technologies used in body part production.