Ideal results

for widely varying strip thicknesses and materials

Our roll forming systems for producing glass spacers are notable for a high production speed of up to 200 metres per minute. Simultaneously they offer you optimum process safety and an extremely low scrap rate.

Always a perfect surface

Our roll forming machines for the production of glass spacers are suitable for a wide range of strip thicknesses – even with a strip thickness of only 0.2 mm you will achieve outstanding results. You can use the roll forming systems to produce glass spacers for aluminium or stainless steel profiles. Dependent on the application and requirement, laser or HF induction welding are used. Moreover, you can produce all usual cross profiles, the changeover from one profile shape to another takes less than 30 minutes. The combination of these advantages means that our roll forming systems pay for themselves more quickly than other systems.

The glass spacers produced on our roll forming systems are generally popular, because they are both clean and dry and have a perfect surface. Similarly, with our roll forming systems you are amongst the environmental trendsetters because you benefit from reduced energy consumption and reduced CO2 emissions. The heading is "thermally cut profiles": Here you profit from our decades of experience in the field of plastic-metal joining technology. This know-how makes us into your reliable partner in the development of new profile concepts with thermal separation.

Examples of roll forming machines

for the production of glass spacers

Examples of roll forming machines for the production of glass spacers provide you with economic and environmental advantages.

Strip feeding systems

- Storage reel for coil diameters of 2300 mm and up to 8 hours running time

- There is only a short stop at the end of the coil thanks to a fast strip end welding machine.

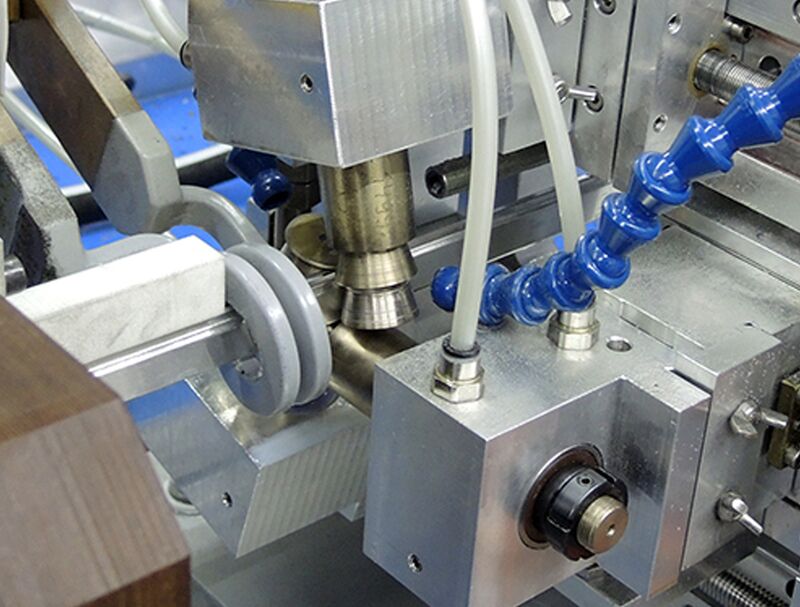

Roll forming Systems

- Optional production rates of 100 to 200 metres per minute

- Dependent on the application and requirements, laser or HF induction welding

- Fast profile change in less than 30 minutes without a crane

Cut-off machines

- Quick revolving cut-off machine for clean cuts without chips