Proven standard solutions

and flexible new production alternatives

Our roll forming machines for drawer sides and rear panels are particularly suited to standard solutions and additionally open up new production options for you: with our flexible roll forming concepts, we support drawer manufacturers in their quest for extra market share.

Quickly serve small market niches

With standard roll forming technology, large quantities can be produced in short periods. However, it is not always sufficient just to produce high quality, but largely uniform mass-produced products: you will be more successful, if you can also serve small market niches with custom tailor-made products in just a short response time. To a large extent, this applies to parts that are visible to the purchaser, as for example drawer sides and rear panels.

The ability to fulfil individual customer wishes means a high product variety and consequently small lot sizes. You can fulfil these requirements with our roll forming machines for drawer sides and rear panels. Flexible roll forming technologies mean you can achieve lighting fast product changes: in less than 15 minutes, your roll forming systems are cleared for starting with the next profile after a product change. This ensures you benefit from high productivity, even with frequent product changes. Therefore, our roll forming systems allow you to implement particularly effective production concepts for order-specific profile production: Also in this way, despite an increasing product variety, you can also reduce your storage costs.

Examples of roll forming machines

for drawer sides and rear panels

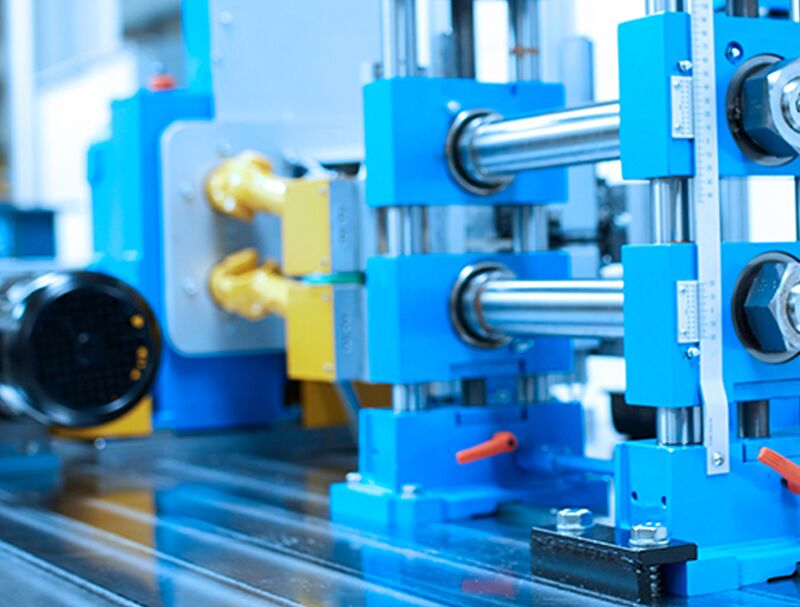

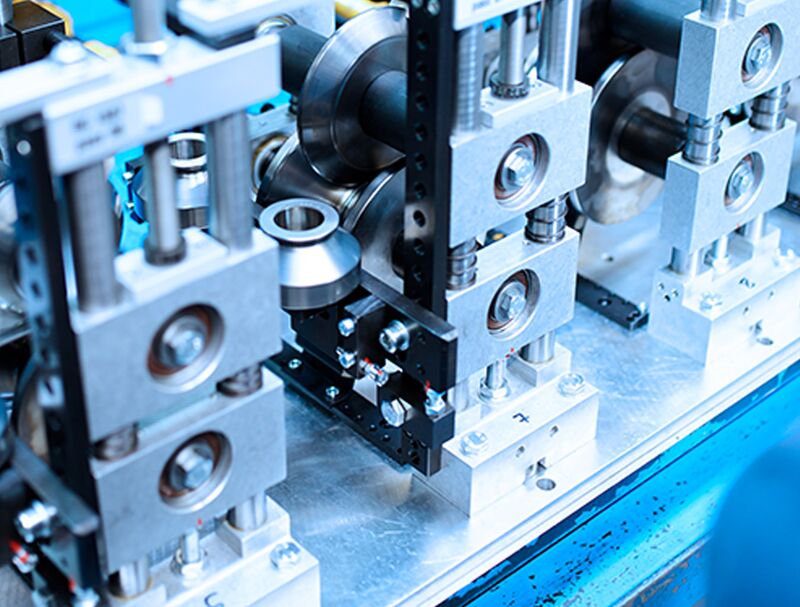

You receive turnkey systems from us with all necessary components based on a technically and economically convincing overall concept.

- Strip preparation systems for coil processing with integrated pre-punching systems and intelligent feed and tool technology for automatic setting up of pre-programmed hole patterns

- Roll forming machines for fast tool change or highly flexible TWIN machine systems

- Flexible double roll forming machines with motorised adjustment axes for simple and quick setup of cross-section dependent dimensions for width and material thickness

- Roll forming tools for mild steel, high-strength steel and all cold-formable materials

- CNC profile punch and cutting unit for post-punching and cutting to length for automatic changeover between length variants

- Tools for piercing, labelling, embossing, etc., as well as cut-off tools for low-burr separation cuts