Reduced scrap for higher yields

Economic and environmental profit through use of innovative roll forming technologies

Less is in every case more: Through our targeted measures and innovative roll forming technologies, we reduce the scrap arising during your roll forming processes. In this way you improve the economic as well as the environmental outcome of your roll forming processes.

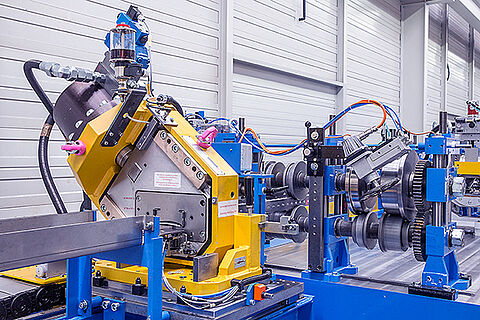

Complete utilisation of the strip

With innovative roll forming technologies, we ensure minimal scrap during production, ensuring the entire strip is used. For example, with two roller feeds the press can make pre-cuts into the flat strip during retracting as well as during extending. When the required production length has been reached, the strip is cut-off directly after the uncoiler. The roll forming system produces acceptable parts, with the exception of a residual piece of about one metre, in the desired batch size and uses the full strip length. A removal unit is installed at the end of the forming line: this ensures the safe removal of the last part.

The residual piece can be pulled out of the roll forming machine and disposed of. No additional tool is required to deplete the machine. If the same profile is run at different lengths, the cut-off machine automatically cuts off any desired variant and does so without material loss. Because the cut-off point is detected depending on the hole pattern, the exact position of the punching pattern is ensured.

A length measurement is incorporated in the cut-off machine. It measures the already produced total length and also the respective product lengths. If the pre-set overall length is reached, the strip stops. The more often the machine is retooled, the more this scrap minimisation will be worthwhile for you.

Contact our roll forming experts

Each process has its own special technological requirements, which is why your company too will have its own special questions about roll forming machines and processes: Our roll forming experts have the answers you need!