Diverse functions skilfully combined

Direct, reliable and economic incorporation of additional processes

Increasing demands on our roll forming technologies include the ever more frequent task of producing roll formed products with an increasing number of functionalities that cannot be realised using roll forming on its own. We integrate the additional methods and processes directly into a roll forming system.

If desired, we can also incorporate bending operations in your roll forming system so that laborious profile handling and additional production facilities are not necessary.

Due to our intensive research and development, we go one step further as part of process integration: our engineers not only target metal forming, but also integrate plastic extruders, PU foaming machines and film coating equipment into the plant.

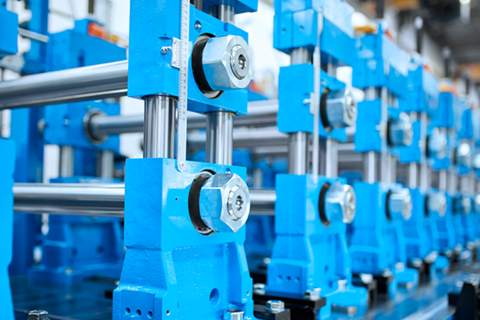

Roll forming machines for professionals, clearly presented

Form your own impressions of the precision and reliability of our roll forming machines: The video clearly shows some of the advantages of our roll forming systems and processes.

Contact our industry experts

Each sector has its own special requirements, which is why your company too will have its own special questions about roll forming machines and processes: Our roll forming process integration experts have the answers you need!