Roll forming 4.0 is reality

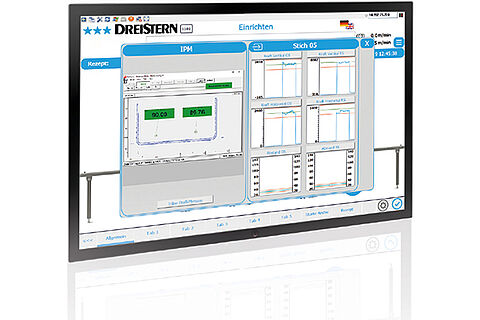

At DREISTERN we have been working on the beneficial use of digitalisation and automation in the roll forming process for quite a few years. Our aim is to exploit the options that are available to us in the here and now for the benefit of our customers and prospective customers.

The latest sensors

The overall aim is improved control of the forming processes based on use of the latest most appropria-te sensors integrated into production and the data obtained from their use. The decisive advantage of the measured values is the development and implementa-tion of helpful assistance systems.Moreover, we are already able to offer the first ready-for-use solutions. If you still need convincing, just contact us!

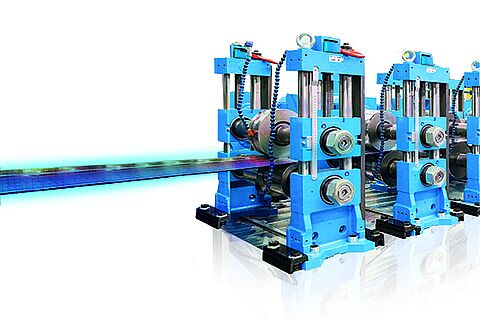

Maximum availability

The trend towards shorter product lifecycles and smaller produc-tion batches requires more frequent product changes. Maximum availability of the roll forming machine together with a minimum scrap rate remain, alongside the functionality of the system and the quality of the sections produced, the decisive factors in profi-table production.