Front and side impact protection

Fulfil the most demanding requirements precisely and efficiently

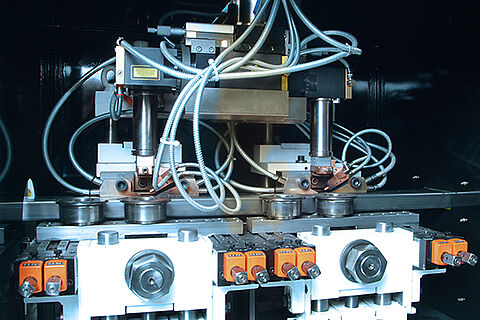

Roll forming processes are established as efficient work steps for the production of ready-to-install lightweight parts for front and side impact protection. For example, with our custom-developed roll forming machines for front and side impact protection, you benefit from very economical processing of ultra-high-strength steels.

High productivity roll forming systems

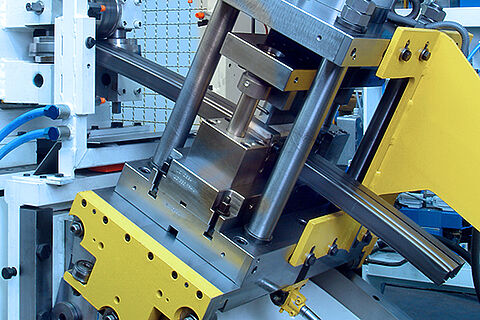

Due to the high stiffness requirements for front and side impact protection profiles, they are designed as welded hollow profiles. Laser welding or spot welding is used dependent on your particular conditions and the relevant cross-section. Our roll forming processes provide ideal conditions for good and fast welding: The achievable welding speeds of 8 to 15 metres per minute are well above the values that are otherwise usual in bodybuilding.

Front and side impact protection profiles are almost always curved along the longitudinal axis. Thanks to integrated bending equipment you can implement any required radii within defined limits. A change of the bending radius means solely a changed setting of the bending tool and has no associated tooling costs. Moreover right and left versions of the parts can be produced using the same roll forming tool, again requiring no extra tooling costs.

Frequently our highly productive roll forming systems are not used to capacity when producing a single product: Thanks to our flexible quick-change concept, you can therefore produce often very different components on our roll forming systems.

Professional roll forming machines clearly presented

Form your own impressions of the precision and reliability of our roll forming machines: The video shows you clearly some of the advantages of our roll forming systems and processes.

Professional roll forming machines clearly presented

Form your own impressions of the precision and reliability of our roll forming machines: The video shows you clearly some of the advantages of our roll forming systems and processes.

Contact our automotive & transport experts

Each sector has its own special requirements, which is why your company too will have its own special questions about roll forming machines and processes: Our roll forming experts in the automotive & transport sector have all the answers you need!