Innovative techniques for every profile

Flexible system concepts with optimised quality standards

The latest roll forming machines and innovative roll forming systems have been our trademark for decades: with our roll forming technologies we are amongst the world’s market leaders. You benefit from our comprehensive know-how and our flexible roll forming concepts, which we develop and implement to exactly match your requirements.

Intelligent stands for the roll forming process

For DREISTERN Industry 4.0 is already a reality. We call it Roll Forming 4.0 and regard it as the future! The task which continually challenges us, and which drives our day-to-day work, is the development of intelligent and market-beneficial roll forming processes based on our

decades of know-how and the available current and future digital options.

You can find comprehensive information here and in the download area.

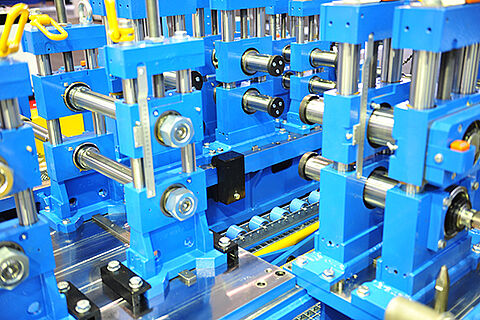

Double roll forming machine DPMflex

The latest generation of our double roll forming machines comes with a whole series of technical advancements, each of which will quickly pay for itself. These include the horizontal axis adjustment of the upper roll axis, a substructure that can be used for two different duplex frames, an increased vertical adjustment range of the duplex frames and the option of using pillar-frames.

You can find comprehensive information in the Download area In the DPMflex machine flyer or in this video.

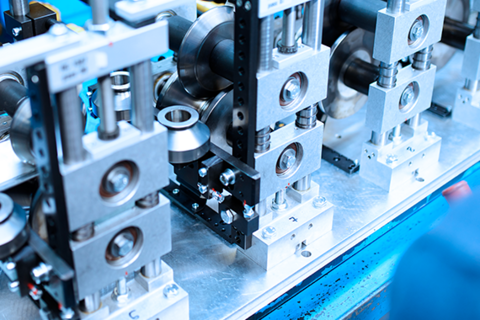

Roll forming machines for thin-walled precision profiles

The P70 roll forming machines offer an impressive range of roll forming applications, from foam-filled aluminium roller blinds and venetian blinds through to welded glass spacers for double glazing. Three different types of frames can be used with this roll forming machine while different additional processes such as foaming, punching and welding can be integrated in it. The ready-to-use tool cassettes make tool changing quick and easy; your production starts again immediately following a product change.

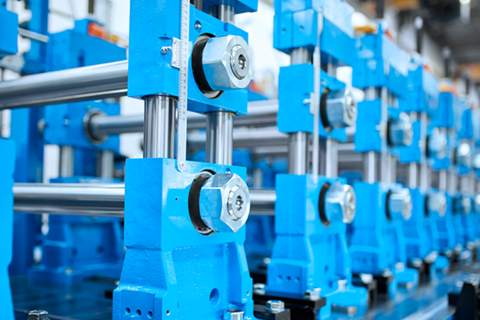

Roll forming machines for medium and heavy profiles

The system concept has exceptional flexibility where your special roll forming requirements are concerned. One outstanding feature is the fast tool change, from which you gain a clear competitive advantage. The consistent concept of the P3 series ensures compatibility: you can use our machine components on a wide variety of machines of various ages and different sizes.

CNC roll forming machines for ultra-flexible profile production

Depending on the type and design, the profile width and height of the CNC roll forming machines can be varied continuously without changing tools. With the ultra-flexible P6/P7 series, the overall measurements of U-, C-, C+- and Sigma profiles can be continuously varied and non-symmetric variants produced. If necessary, we integrate an automatic sheet thickness adjustment. These roll forming machines are ideal for processing plates; they are often used in the production of Dry lining profiles, Cable trays, Switch cabinet parts and Rack posts.

Make use of our roll forming expertise

Our cutting-edge technologies for roll forming machines, will provide you with a significant competitive advantage. This is documented by the many roll forming systems, that have established us as a world leader in our market.

Contact our roll forming experts

Each process has its own special technological requirements, which is why your company too will have its own special questions about roll forming machines and processes: our roll forming experts have the answers you need!